What is the technology of Lab Grown Diamonds? What processes are used to produce Lab Grown Diamonds? What are the processes for growing Man Made Diamonds? Can real diamonds actually be grown in the laboratory today? What is a HPHT diamond? What is HPHT? What is High Pressure High Temperature Process? What is a CVD diamond? What is CVD? What is Chemical Vapor Deposition? What are the differences of HPHT diamond and CVD diamond? Are HPHT and CVD diamonds different? Which is better HPHT diamond or CVD diamond?

Lab Grown Diamonds – Cultured Diamonds – laboratory diamonds – cultivated diamonds (incorrectly: synthetic diamonds, artificial diamonds)

Mining diamonds: Mining causes holes, mineral waste, huge energy and water consumption.

Overexploitation of nature and resources. Dangerous and often poorly paid jobs. Origin? Blood diamonds? War funding?

Thanks to technological progress, real diamonds can now be grown in the laboratory. It sounds almost too good to be true, but corresponds to the facts: 100% real diamonds in amazing quality and large sizes can be cultivated.

What are the manufacturing processes and main advantages of Lab Grown Diamonds?

Both methods of growing Lab Grown Diamonds look at where and how diamonds exist in nature. Exactly these natural conditions are imitated for breeding Lab Grown Diamonds.

The advantages of Lab Grown Diamond are reasonable price, top quality, environmental friendly and ethical.

Bedingungen in der Natur werden imitiert:

HPHT (High Pressure High Temperature) -> Erde

CVD (Chemical Vapor Deposition) -> Galaxy, interstellare Gaswolken, Eisplaneten wie Neptun und Uranus

- cheaper

- Top quality

- environmentally friendly

- ethical

Is the clarity of Lab Grown Diamonds better than that of mined diamonds?

Are all Lab Grown Diamonds Internally Flawless? Do lab diamonds all have perfect clarity?

No, Lab Grown Diamonds, like mine diamonds, have different pure rides. Since the growing process imitates natural conditions, the same imperfections as in nature can occur in terms of color, clarity, etc.. They are also classified with the same 4Cs Carat, Color, Clarity and Cut as mined diamonds.

Is the quality of Lab Grown Diamonds better than that of mined diamonds?

Are Lab Grown Diamonds better quality than mine diamonds?

High quality manufacturers are very strive to produce good quality with latest technology and research. These Lab Grown Diamonds tend to have better qualities than mine diamonds because they are Type IIa. For low quality producers, the focus is on rapid breeding and profit maximization.

What is a Lab Grown Diamond? What is a laboratory diamond?

A “lab diamond” is a man-made diamond that has been grown in a laboratory environment by one of the two currently available manufacturing processes:

HPHT (High Pressure High Temperature)

CVD (Chemical Vapor Deposition)

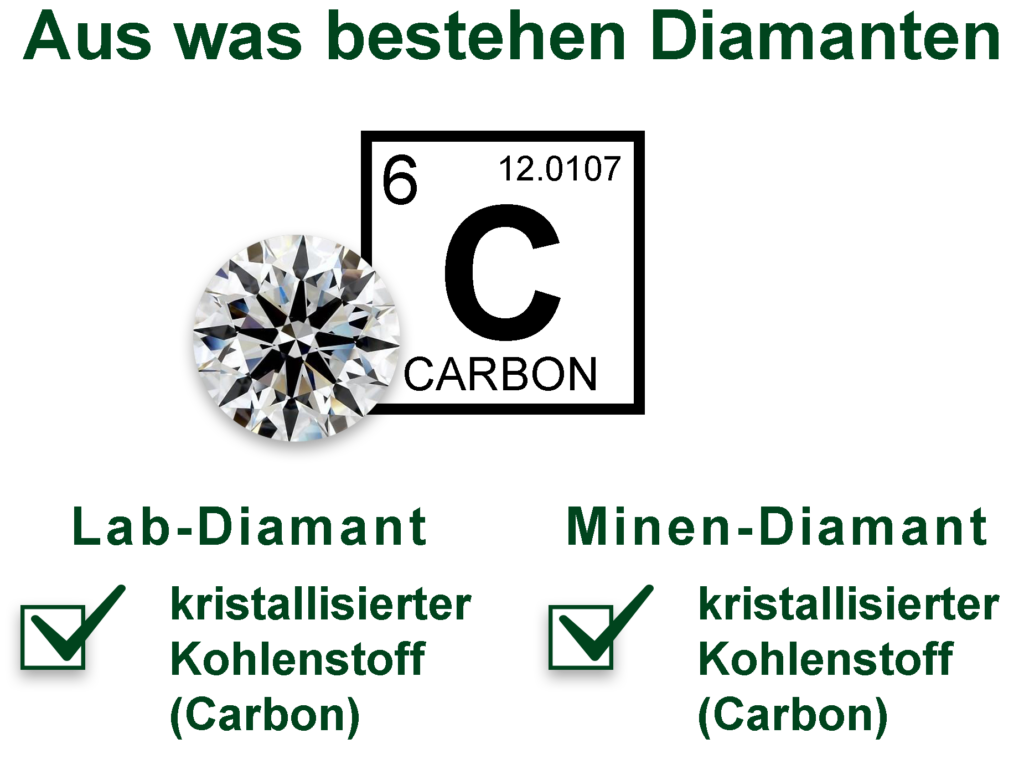

Are Lab Grown Diamonds real diamonds? What material are diamonds made of? What are Lab Grown Diamonds made of? What is the atomic lattice structure of Lab Grown Diamonds?

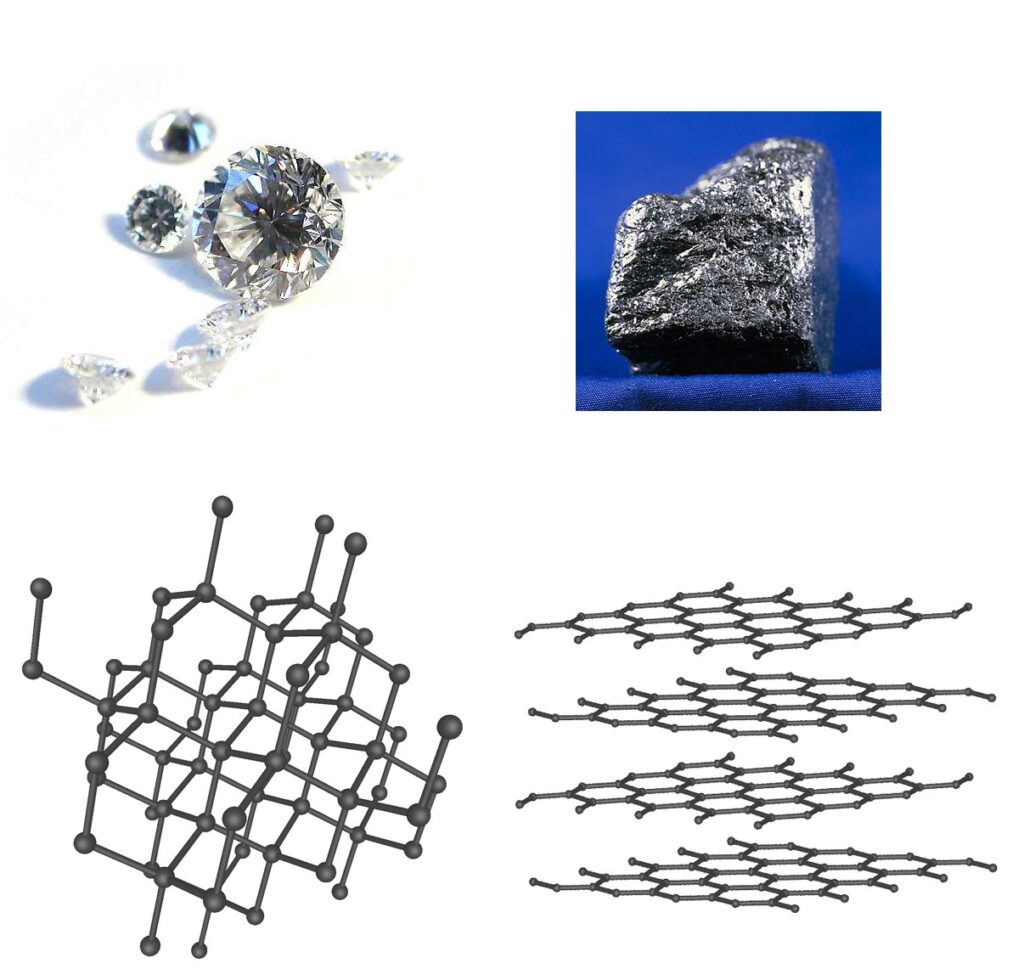

All genuine diamonds are made of pure crystallized carbon (pure carbon); this applies to both mine diamonds and lab diamonds. The growing process mimics/imitates natural growth in the deep interior of the Earth (HPHT) or in interstellar gas clouds (CVD).

Although the growth process is different from what occurs in nature, the chemical composition, physical properties, and optical properties in lab-grown diamonds are identical to those of diamonds mined/extracted from mines .

Lab-grown diamonds come in all sizes (currently up to over 10 carats), all shapes and all colors, and the light output is identical to that of mined diamonds.

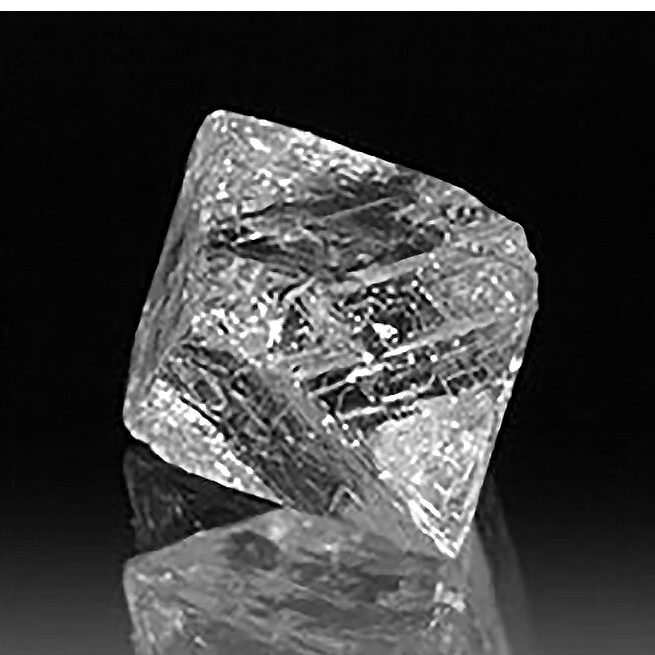

HPHT (High Pressure, High Temperature)

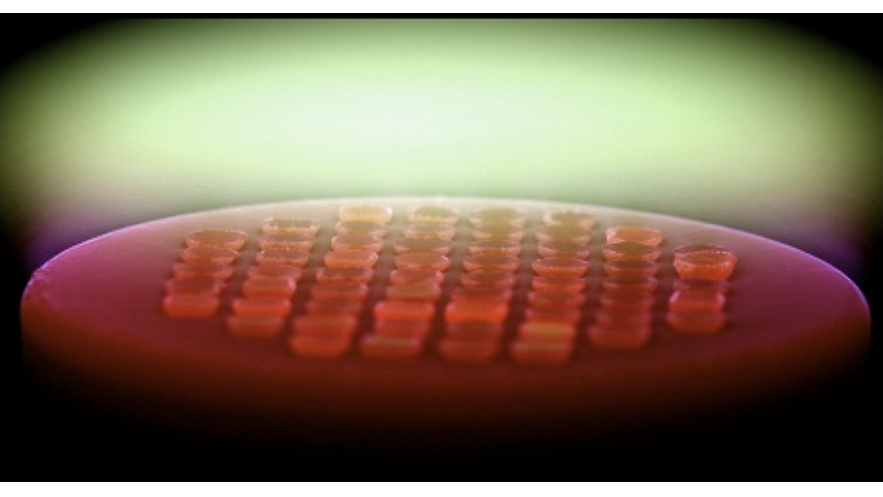

In HPHT synthesis, a press applies extremely high pressures and temperatures to a central growth chamber containing the necessary ingredients. This results in lab diamond crystals with combinations of cubic and octahedral faces. Similar to a honeycomb structure with squares.

HPHT

- Analog conditions deep earth

- Approx. 1’500 °Celsius (extremely high temperature)

- 400 tons per square inch (extremely high pressure)

Using the traditional diamond growth method “High Pressure High Temperature (HPHT) method”, Lab grown Diamonds are produced from carbon material in apparatus that mimics the high pressure high temperature conditions of natural diamond formation in the earth. This diamond growth process exposes carbon to extreme temperatures and pressures, replicating the extreme heat and pressure conditions deep within the Earth where mined diamonds form.

- Diamond seed is placed in a specially developed press:

This is a capsule in an apparatus capable of generating very high pressure. - Growth chamber is heated to 1’300-1’600 °C with pressures above 400 tons per square inch:

Inside the capsule, a carbon feedstock such as graphite dissolves in a molten flux consisting of metals such as iron (Fe), nickel (Ni), or cobalt (Co), lowering the temperature and pressure required for diamond growth. - The molten metal dissolves the high purity carbon source

- Carbon atoms are deposited on a small diamond seed crystal:

→ Lab diamond begins to grow

The carbon material/atoms then migrate through the flux to the cooler diamond seed crystal and crystallize/grow on it to form a lab grown diamond crystal. - Crystallization takes place over a period of several weeks to months to grow one or more crystals

- This grown rough diamond is then cut, ground and polished by a diamond cutter

Growing colorless HPHT Lab diamonds was once a challenge. Nitrogen, which turns diamonds yellow, had to be kept away from the growing environment. In addition, growing high-purity colorless diamonds required longer growth times and better control of growth temperature and pressure conditions. However, recent technological advances have allowed laboratories to produce colorless crystals that are faceted as diamonds of 10 carats or more.

How are colored diamonds Yellow, Blue, Pink Lab Grown Diamonds?

The addition of nitrogen during the growth process leads to yellow crystals, while the addition of boron leads to blue crystals. Other colors – such as pink and red – can be produced by radiation and heating, but are less common.

You can find more details about Fancy Color Diamonds here.

Herstellung Fancy Color Diamanten

Zugabe Stickstoff → Yellow Diamanten

Zugabe Bor → Blue Diamanten

Strahlung & Erwärmung → Pink & Red Diamanten (seltener)

CVD (Chemical Vapor Deposition)

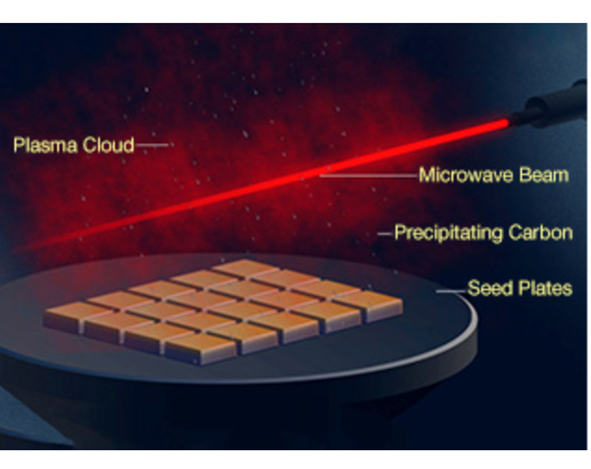

In CVD synthesis, microwaves split the hydrocarbon molecules fed into the reactor. These fragments migrate downward to the colder diamond nucleus and attach to the growing diamond surface. The Lab diamond grows in thin layers, and its final thickness depends on the time available for growth. The result is flat, tabular crystals (similar to a cube) whose outer surface is coated with black graphite.

CVD

- Analogous conditions of interstellar gas clouds (how cool is that?) and icy planets like Neptune and Uranus.

- Gas (methane)

- Vacuum chamber

- Approx. 1’000 °Celsius (high temperature, lower than HPHT)

- Microwave beam

Chemical vapor deposition (CVD) is a newer technique used to grow diamonds from a hydrocarbon gas mixture (e.g. methane). In the CVD process, a thin slice of a diamond seed (often an HPHT diamond) is placed in a sealed vacuum chamber and heated to about 900 degrees Celsius. A source of energy – such as a microwave beam – breaks down the gas molecules, and the carbon atoms diffuse toward the colder, flat diamond seed plates.

- Diamond seed crystals → placed in diamond growth chamber

- Chamber is filled with carbonaceous gas

- Chamber is heated to about 900-1’200°C

- A microwave beam causes carbon to precipitate from a plasma cloud and deposit on a seed crystal.

- The diamonds are removed every few days to polish the surface to remove any non-diamond carbon before being put back in for waxing. Each batch of diamonds may require multiple stop/start cycles.

- Crystallization takes place over a period of weeks, with several crystals growing simultaneously.

- This grown rough diamond is then cut, ground and polished by a diamond cutter.